In an era where the construction and interior design industries increasingly prioritize sustainability and performance, wood plastic composite cladding has emerged as a modern flooring material gaining widespread attention. This innovative product combines natural wood fibers with recycled plastic through advanced granulation and extrusion processes, preserving the natural texture of wood while enhancing durability through plastic's inherent advantages.

Compared to traditional timber, plastic composite cladding offers superior resistance to moisture, corrosion, insects, and mold. It is especially well-suited for humid, high-traffic, and deformation-prone environments. Whether used in outdoor gardens, waterfront walkways, café terraces, or indoor kitchens, bathrooms, and washrooms, it stands out as a high-performance alternative to natural wood and ceramic tiles.

Thanks to its excellent physical properties and adaptability, wood plastic composite cladding has found broad applications in diverse settings:

Outdoor Use: Ideal for landscaping paths, boardwalks, patios, fences, docks, balconies, and more. It withstands rain, UV exposure, and temperature fluctuations.

Indoor Use: Perfect for bathrooms, kitchens, and laundry rooms where water resistance and anti-slip safety are essential.

In addition, plastic composite cladding is also widely applied in commercial spaces such as cafés, bars, and exhibition halls. Its natural wood grain texture and rich color options bring warmth and sustainability to interiors, enhancing the overall ambiance.

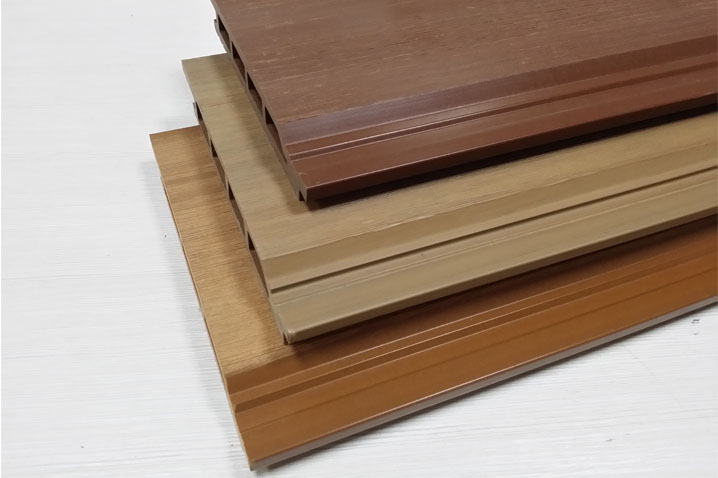

The following chart outlines two common types of wood plastic composite cladding and their respective features, helping users make informed choices based on specific needs:

| Type | Production Structure | Surface Treatment | Performance Characteristics |

|---|---|---|---|

| Non-coextruded Flooring | Mixed extrusion molding of wood powder + HDPE | Can be sanded, grooved, or 3D embossed | Natural wood grain, anti-slip, wear-resistant, waterproof, consistent color between core and surface, high cost performance |

| Coextruded Flooring | Covered with a high polymer protective layer | Smooth or embossed surface | Stronger stain resistance, UV resistance, corrosion resistance, suitable for high-end outdoor venues |

With a range of styles and structural options, plastic composite cladding meets the modern demand for beauty, performance, and environmental responsibility.

Choosing wood plastic composite cladding means embracing a material that values aesthetics, safety, and sustainability. Key advantages include:

Superior Performance: High strength, slip resistance, anti-aging, corrosion resistance, termite-proof, dimensionally stable, and suitable for a wide range of climates.

Eco-Friendly: Made from renewable and recyclable raw materials, free from formaldehyde, benzene, or harmful emissions—100% recyclable and truly sustainable.

Low Maintenance: No need for annual repainting; simple rinsing with water keeps it clean, significantly reducing upkeep time and cost.

Naturally Beautiful: Authentic textures and diverse color choices offer the warmth of natural wood without the drawbacks. Customizable designs ensure broad compatibility with different décor styles.

Easy Installation: Modular interlocking systems allow for quick and simple installation without special tools or complex procedures, reducing labor and construction time.

From structure and performance to aesthetic appeal and eco-conscious design, plastic composite cladding is quickly becoming an essential part of the modern building materials landscape. If you're in search of a flooring solution that combines the charm of natural wood with advanced functionality, wood plastic composite cladding is a choice worth serious consideration. In the near future, it may well replace traditional wood as the smarter, greener, and more enduring material for the spaces where we live and work.